Windmill

A windmill is a machine which converts the energy of wind to rotational motion by means of adjustable vanes called sails. The main use is for a grinding mill powered by the wind, reducing a solid or coarse substance into pulp or minute grains, by crushing, grinding, or pressing.[1][2] Windmills have also provided energy to sawmills, paper mills, hammermills, and windpumps for obtaining fresh water from underground or for drainage (especially of land below sea level).

Contents |

History

The windwheel of the Greek engineer Heron of Alexandria in the 1st century marks one of the first known instances of wind powering a machine in history.[3][4] Another early example of a wind-driven wheel was the prayer wheel, which was used in ancient Tibet and China since the 4th century.[5]

Vertical-axis windmills

The first practical windmills were the vertical axle windmills invented in eastern Persia (or in modern-day western Afghanistan), as recorded by the Persian geographer Estakhri in the 9th century.[6][7] The authenticity of an earlier anecdote of a windmill involving the second caliph Umar (AD 634–644) is questioned on the grounds that it appears in a 10th-century document.[8] Made of six to twelve sails covered in reed matting or cloth material, these windmills were used to grind grain or draw up water, and were quite different from the later European horizontal-axis versions. Windmills were in widespread use across the Middle East and Central Asia, and later spread to China and India from there.[9]

Some popular treatments of the subject have speculated that, by the 9th century, the Afghanistan-style vertical-axle mills spread to Europe through Al-Andalus (Islamic Spain).[10] This has been denied by the specialist of medieval European technology, Lynn White Jr., who points out that there is no evidence (archaeological or documentary) that the Afghanistan-style vertical-axle windmill spread as far west as Al-Andalus,[11] and notes that "all Iberian windmills rotated on horizontal axles until towards the middle of the fifteenth century."[12] Another historian of technology, Michael Jonathan Taunton Lewis, suggested an alternative route of transmission for the Islamic horizontal-shaft windmill, with its diffusion to the Byzantine Empire and its subsequent transformation into the vertical-shaft windmill in Europe.[13] Late medieval vertical-axle windmills similar to the Islamic/Persian design can be found along this route, particularly in Karpathos, Greece, and Kandia, Crete. The Crusades has also been suggested as another possible route of transmission, though in the sense of "stimulus diffusion," where the idea was diffused rather than the technology itself.[14] However, the debate about whether the European vertical-shaft windmill evolved from the Islamic horizontal-shaft windmill or was an independent development remains unresolved.[13]

Horizontal-axis windmills

Fixed windmills, oriented to the prevailing wind were extensively used in the Cyclades islands of Greece. The economies of power and transport allowed the use of these 'offshore' mills for grinding grain transported from the mainland and flour returned. A 1/10th share of the flour was paid to the miller in return for his service. This type would mount triangular sails when in operation.

A similar type of vertical-shaft windmill with rectangle blades, used for irrigation, can also be found in 13th-century China (during the Jurchen Jin Dynasty in the north), introduced by the travels of Yelü Chucai to Turkestan in 1219.[15]

Horizontal-axle windmills that turn to face the wind

In northwestern Europe, the horizontal-axle or vertical windmill (so called due to the dimension of the movement of its sails) dates from the last quarter of the 12th century in the triangle of northern France, eastern England and Flanders. Lynn White Jr. claims that the first certain reference to the European horizontal-axle windmill is dated to 1185 in Weedley, Yorkshire.[16] (This predates Joseph Needham's claim that the earliest known reference is from the 1191 chronicle of Jocelin of Brakelond, in which a Dean Herbert of East Anglia supposedly competed with the mills of the abbey of Bury St Edmunds).[17] These earliest mills were used to grind cereals. The evidence at present is that the earliest type was the sunk post mill, so named because of the large upright post on which the mill's main structure (the "body" or "buck") is balanced. By mounting the body this way, the mill is able to rotate to face the wind direction; an essential requirement for windmills to operate economically in North-Western Europe, where wind directions are variable. By the end of the thirteenth century the masonry tower mill, on which only the timber cap rotated rather than the whole body of the mill, had been introduced. In the Netherlands these stone towerlike mills are called "round or eight-sided stone stage mills, ground-sailers (windmills with sails reaching almost down to the ground), mound mills, etc." (Dutch: ronde/achtkante stenen stelling molens, grond-zeilers, beltmolens, etc.). Dutch tower mills ("torenmolens") are always cylindrical (such as atop castle or city wall towers). Because only the cap of the tower mill needed to be turned the main structure could be made much taller, allowing the sails to be made longer, which enabled them to provide useful work even in low winds. Such mills often have a small auxiliary set of sails called a fantail at the rear of the cap and at right angles to the sails; this rotates the cap through gearing so that the sails face into the wind.

-

-

- Post mills in Germany are Bockwindmühlen, Paltrockmühlen or Wippmühlen.

- Smock mills in Germany can be Sockelgeschoßholländer or Galerieholländer.

- Tower mills in Germany can be Turmholländer, Galerieholländer, Erdholländer or Bergholländer

-

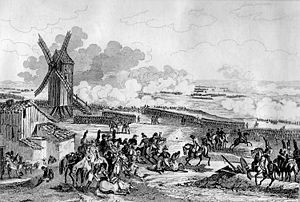

Windmills were often built on top of castle towers or city walls, and were a unique part of a number of fortifications in New France, such as at Fort Senneville.

The familiar lattice style of windmill sails (also called "common" sails) allowed the miller to attach sailcloths to the sails (while applying a brake). Trimming the sails allowed the windmill to turn at near the optimal speed in a large range of wind velocities. The fantail, a small windmill mounted at right angles to the main sails which automatically turns the heavy cap and main sails into the wind, was invented by Edmund Lee in 1745, in England. The smock mill is a later variation of the tower mill, constructed of timber and originally developed in the sixteenth century for land drainage. With some subsequent development mills became versatile in windy regions for all kind of industry, most notably grain grinding mills, sawmills (late 16th century), threshing, and, by applying scoop wheels, Archimedes screws, and piston pumps, pumping water either for land drainage or for water supply. In 1772, Scottish millwright, Andrew Meikle developed the spring sail made from a series of connected parallel shutters that could be opened or closed according to windspeed. To do this the sails had to be stopped, but the sails also incorporated a spring which allowed the shutters to open a little more to prevent damage if the wind suddenly strengthens. In 1789, Stephen Hooper invented the roller reefing sail, which allowed automatic adjustment of the sail whilst in motion. In 1807, William Cubitt a Norfolk engineer, invented a new type of sail, known there on as patent sails, using a chain and a rod that passed through the centre of the windshaft. These sails had the shutters of Meikle's spring sails and the automatic adjustment of Hooper's roller reefing sails. This became the basis of self-regulating sails. These avoided the constant supervision that had been required up till then.

By the 19th Century there were some 10,000 corn mills operating in Britain,[18] but with the coming of the industrial revolution, the importance of wind as primary industrial energy source was replaced by steam and internal combustion engines. The increased use of steam, and later diesel power, however, had a lesser effect on the mills of the Norfolk Broads, these being so isolated (on extensive uninhabitable marshland) that some of them continued in use as drainage pumps powered by diesel until as late as 1959. More recently windmills have been preserved for their historic value, in some cases as static exhibits when the antique machinery is too fragile to put in motion, and in other cases as fully working mills. There are around 50 working mills in operation in Britain as of 2009.[18]

Rule of thumb

Such was the importance of the corn mills of Britain that a number of phrases used in their operation have found their way into common usage in the English language: When the wind was not strong enough to turn the sails the millstones would "grind to a halt", and the coarseness of the ground flour was assessed by the miller rubbing it between his thumb and forefinger, possibly giving rise to the term "rule of thumb".[18]

See Flood control in the Netherlands for use of windmills in land reclamation in the Netherlands.

In Canada and the United States

Windmills feature uniquely in the history of New France, particularly in Canada, where they were used as strong points in fortifications.[19] Prior to the 1690 Battle of Québec, the strong point of the city's landward defenses was a windmill called Mont-Carmel, where a three-gun battery was in place.[19] At Fort Senneville, a large stone windmill was built on a hill by late 1686, doubling as a watch tower.[20] This windmill was like no other in New France, with thick walls, square loopholes for muskets, with machicolation at the top for pouring lethally hot liquids and rocks onto attackers.[20] This helped make it the "most substantial castle-like fort" near Montreal.[21]

In the United States, the development of the water-pumping windmill was the major factor in allowing the farming and ranching of vast areas of North America, which were otherwise devoid of readily accessible water. They contributed to the expansion of rail transport systems throughout the world, by pumping water from wells to supply the needs of the steam locomotives of those early times. Two prominent brands were the Eclipse Windmill developed in 1867 (which was later bought by Fairbanks-Morse) and the Aermotor, which first appeared in 1888 and is still in production. The effectiveness of the Aermotor's automatic governor, which prevents it from flying apart in a windstorm, led to its popularity over other models. Currently, the Aermotor windmill company is the only remaining water windmill manufacturer in the United States. They continue to be used in areas of the world where a connection to electric power lines is not a realistic option.[22]

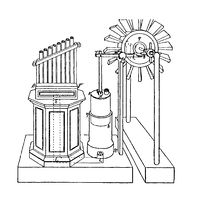

The multi-bladed wind turbine atop a lattice tower made of wood or steel was, for many years, a fixture of the landscape throughout rural America. These mills, made by a variety of manufacturers, featured a large number of blades so that they would turn slowly with considerable torque in low winds and be self regulating in high winds. A tower-top gearbox and crankshaft converted the rotary motion into reciprocating strokes carried downward through a rod to the pump cylinder below.

Windmills and related equipment are still manufactured and installed today on farms and ranches, usually in remote parts of the western United States where electric power is not readily available. The arrival of electricity in rural areas, brought by the Rural Electrification Administration (REA) in the 1930s through 1950s, contributed to the decline in the use of windmills in the US. Today, the increases in energy prices and the expense of replacing electric pumps has led to an increase in the repair, restoration and installation of new windmills.

- 1980s Wind Energy Experiment

In the early 1980s, several small companies started wind farms for commercial energy production in the San Joaquin valley region of California. The first such wind farm was created in 1981 when John Eckland, of Fayette Manufacturing Corporation placed the first windmills on land leased from Joe Jess, Sr. on the Altamont Pass. Later, as a gift to Mr. Jess for the continued use of his land, Fayette created a ‘stars and stripes’ themed windmill.[23][24][25]

At one point in the mid-80s there were over twenty-six wind farm companies operating in this area of the United States. This eventually expanded to areas outside of Palm Springs, as seen as backdrops in several films of the era, such as Less Than Zero. However, later legislative efforts by California lawmakers eliminated the financial incentives and tax breaks that made these early alternative energy projects feasible (Fisher, 1985). Similar tax credits and incentives have brought a resurgence in interest in renewable energy sources in other areas of the country (Maloney, 2006).[23][24][25]

Multi-sailed windmills

The majority of windmills had four sails. An increase in the number of sails meant that an increase in power could be obtained, at the expense of an increase in the weight of the sail assembly. The earliest record of a multi-sailed mill in the United Kingdom was the five sail Flint Mill, Leeds, mentioned in a report by John Smeaton in 1774. Multi-sailed windmills were said to run smoother than four sail windmills. In Lincolnshire, more multi-sailed windmills were found than anywhere else in the United Kingdom. There were five, six and eight sail windmills.[26]

If a four sail windmill suffers a damaged sail, the one opposite can be removed and the mill will work with two sails, generating about 60% of the power that it would with all four sails. A six sail mill can run with two, three, four or six sails. An eight sail mill can run with two, four, six or eight sails, thus allowing a number of options if an accident occurs. A five sail mill can only run with all five sails. If one is damaged then the mill is stopped until it is replaced.[26] Apart from the UK, multi-sail mills were built in Germany, Malta and the USA.

See also

- American Wind Power Center in Lubbock, TX

- Éolienne Bollée

- List of windmills

- Mill machinery

- Molinology

- Renewable energy

- Thomas O. Perry

- Watermill

- Runner stone

References

- ↑ Mill definition

- ↑ Windmill definition stating that a windmill is a mill or machine operated by the wind

- ↑ A.G. Drachmann, "Heron's Windmill", Centaurus, 7 (1961), pp. 145-151

- ↑ Dietrich Lohrmann, "Von der östlichen zur westlichen Windmühle", Archiv für Kulturgeschichte, Vol. 77, Issue 1 (1995), pp.1-30 (10f.)

- ↑ Lucas, Adam (2006), Wind, Water, Work: Ancient and Medieval Milling Technology, Brill Publishers, p. 105, ISBN 9004146490

- ↑ دانره المعارف بزرگ اسلامی - اصطخري، ابواسحاق

- ↑ Ahmad Y Hassan, Donald Routledge Hill (1986). Islamic Technology: An illustrated history, p. 54. Cambridge University Press. ISBN 0-521-42239-6.

- ↑ Dietrich Lohrmann, "Von der östlichen zur westlichen Windmühle", Archiv für Kulturgeschichte, Vol. 77, Issue 1 (1995), pp.1-30 (8)

- ↑ Donald Routledge Hill, "Mechanical Engineering in the Medieval Near East", Scientific American, May 1991, p. 64-69. (cf. Donald Routledge Hill, Mechanical Engineering)

- ↑ Farrokh, Kaveh (2007), Shadows in the Desert, Osprey Publishing, p. 280, ISBN 1846031087

- ↑ Lynn White Jr. Medieval technology and social change (Oxford, 1962) p. 86

- ↑ Lynn White Jr. Medieval technology and social change (Oxford, 1962) p. 161-162

- ↑ 13.0 13.1 Lucas, Adam (2006), Wind, Water, Work: Ancient and Medieval Milling Technology, Brill Publishers, pp. 106–7, ISBN 9004146490

- ↑ Bent Sorensen (November 1995), "History of, and Recent Progress in, Wind-Energy Utilization", Annual Review of Energy and the Environment 20: 387–424, doi:10.1146/annurev.eg.20.110195.002131

- ↑ Needham, Volume 4, Part 2, 560.

- ↑ Lynn White Jr. Medieval technology and social change, Oxford, 1962, p. 87.

- ↑ Needham, Volume 4, Part 2, 555.

- ↑ 18.0 18.1 18.2 Victorian Farm, Episode 1. Directed and produced by Naomi Benson. BBC Television

- ↑ 19.0 19.1 Chartrand, French Fortresses in North America 1535–1763: Québec, Montréal, Louisbourg and New Orleans

- ↑ 20.0 20.1 Chartrand, p 41

- ↑ Chartrand, p. 38

- ↑ Quirky old-style contraptions make water from wind on the mesas of West Texas

- ↑ 23.0 23.1 Land Use Cooperative article from 1985

- ↑ 24.0 24.1 (2006) Maloney, P. New York Times, May 17th. 2006.

- ↑ 25.0 25.1 The threat to wind energy, special report. (1985). Fisher, B. New York Times, October 26, 1985.

- ↑ 26.0 26.1 Wailes, Rex (1954), The English Windmill, London: Routlege & Kegan Paul, pp. 99–104

- A.G. Drachmann: "Heron's Windmill," Centaurus, 7 (1961), pp. 145–151

Further reading

- Ahmad Y Hassan, Donald Routledge Hill (1986). Islamic Technology: An illustrated history. Cambridge University Press. ISBN 0-521-42239-6.

- Chartrand, French Fortresses in North America 1535–1763: Québec, Montréal, Louisbourg and New Orleans.

- Dietrich Lohrmann, "Von der östlichen zur westlichen Windmühle", Archiv für Kulturgeschichte, Vol. 77, Issue 1 (1995)

- A.G. Drachmann, "Heron's Windmill", Centaurus, 7 (1961).

- Needham, Joseph (1986). Science and Civilization in China: Volume 4, Physics and Physical Technology, Part 2, Mechanical Engineering. Taipei: Caves Books Ltd.

- Hugh Pembroke Vowles: "An Enquiry into Origins of the Windmill", Journal of the Newcomen Society, Vol. 11 (1930–31)

- Roy Gregory and Laurence Turner (2009) Windmills of Yorkshire ISBN 9781840334753

- Edwin Tunis (1999), Colonial living, The Johns Hopkins University Press ", ISBN 0-8018-6627-2, pp. 72 and 73

External links

- Architecture: Windmills at the Open Directory Project

- Earth Science Australia, Wind Power and Windmills

- The International Molinological Society

- Windmills at Windmill World

- The Mill Database, Europe

- Rottingdean smock mill, Sussex UK, photo gallery

|

||||||||||||||||||||||